A milling machine uses a multi-toothed or fluted cutter to remove material from a workpiece. Milling machines are some of the most useful and versatile types of machine tools and as such are found in almost every machine shop, workshop and maintenance department.

Milling machines come in many sizes and forms. They range from compact, hand-operated units that a hobbyist might use in a garage, shed or barn to large, computer-controlled equipment producing complex, high-precision tools and parts.

The principal distinction between types of milling machines is whether their cutting axis is horizontal or vertical. Here we’ll explain why this matters and the factors influencing which type to use. First though: cutting tools.

The Cutting Tool

Material is removed by a rotating circular cutting tool with “teeth” that take “bites” out of the workpiece. There are many different types of milling cutters. Selection depends on workpiece geometry and the type of milling machine being used.

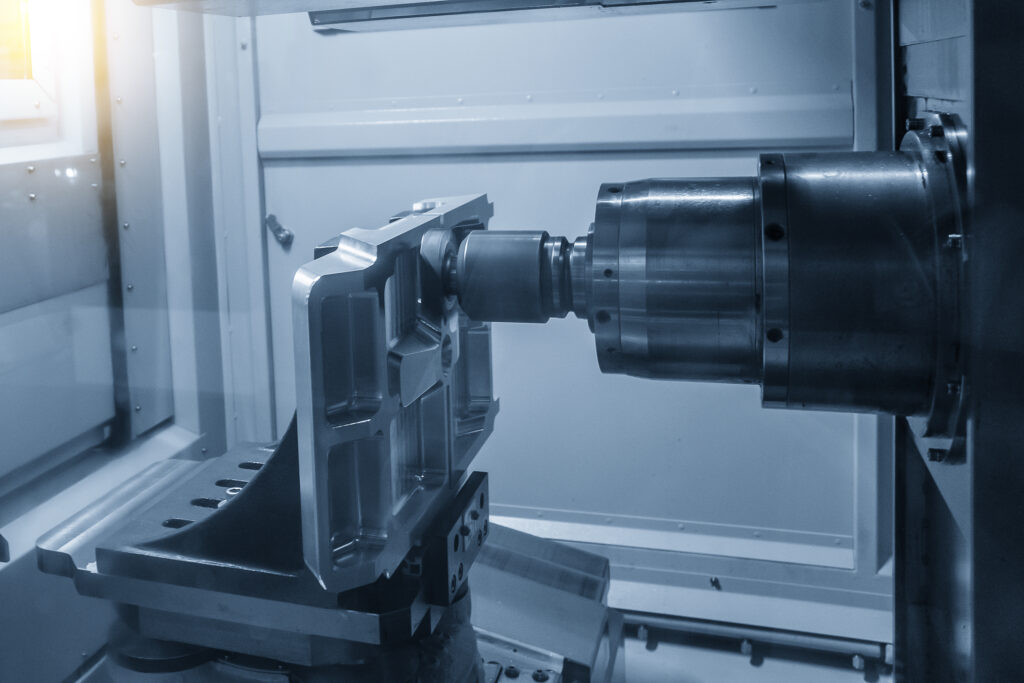

Milling cutters are interchangeable, and a machinist will swap them over to produce particular features. (In an automated CNC milling machine this might be accomplished with an automatic tool changer.) Cutters are generally clamped into the machine spindle by some form of collet mechanism. This often has tapered surfaces and a drawbar that pulls the tool in tight against a datum to ensure a rigid and repeatable non-slip mounting.

Vertical Milling Machines

A vertical mill has the cutting tool axis oriented vertically. The workpiece is clamped to a table that moves in X and Y directions beneath the tool. Z-axis or height changes are accomplished either by raising and lowering the table or by doing the same with the spindle. The former is referred to as a turret-type vertical mill while the latter is a bed-type.

The main strength of vertical milling machines are:

- Don’t take up much space

- Very versatile – can perform a wide range of milling operations

- Cutting zone remains visible

- Less expensive than horizontal mills

- Commonplace, as are the skills needed to operate one

Horizontal Milling Machines

In a horizontal mill, the cutting tool rotates about a horizontal axis. In some machines, this extends across the width of the bed with the cutter mounted on a shaft or arbor held at both ends. More commonly, especially in newer machines, the cutter is mounted into a horizontal collet that can move up and down. As with the vertical machine, the table can move in X and Y directions for a total of three axes.

For some types of work horizontal mills have advantages over vertical machines. These include:

- Ideal for cutting long slots

- Cleaner – gravity takes chips and coolant away from the cutting zone

- More rigid construction, so can remove metal faster and achieve better finishes

However, they also tend to be larger and more expensive. Despite this, some machine shops find the costs and benefits of horizontal machining outweigh the downsides.

The Equipment Hub for Your Milling Machine Needs Whether you need a vertical or horizontal mill, finding one that’s exactly right for your needs, space and budget takes effort. Save time and avoid the risk of making the wrong choice by working with our specialists. They’ll listen to what you need and help you find the right machine.

Sign Up for Our Newsletter

Sign up for our newsletter using the form below to get company insights and updates directly in your inbox!