Manufacturers are looking to CNC machines for custom-built parts with more accuracy and less error. When it comes to CNC cutting machines, CNC Mills and CNC Routers are two that come to mind. Similar, yet different. That’s the best way to summarize these two types of machine tools. They have much in common, yet their design and construction result different uses. Here we’ll compare the two, but we’ll begin with a CNC primer for anyone unfamiliar with the term.

What is a CNC Machine?

CNC stands for Computerized Numerical Control. In manufacturing, CNC machining refers to having a computer send speed, acceleration, and position commands to the motors driving each axis of a machine tool. Feedback from encoders on the machine enables closed-loop control for high accuracy and repeatability. CNC can control a scope of complex machines including lathes, lasers, plasmas, punches, waterjets, and more. These machines are used in various industries on different materials. Unlike additive manufacturing, all CNC machines subtract from the material to create the end product.

A part program generated from a CAD file dictates a sequence of moves that enable the machine to cut, A part program generated from a CAD file dictates a sequence of moves that enable the machine to cut, turn or drill complex shapes. A CNC machine executes this part program to produce one or many parts. The machine can run unattended other than for unloading and loading. Each part will be identical, within the repeatability limits of the machine, and subject to tool wear effects. This manufacturing process produces parts in less time, with less waste, and less error.

CNC Routers

A CNC router is a computer controlled cutting machine that holds the cutting tool in a vertical spindle. The spindle can move left-right while the table moves forward and back for 2 axes of motion. In addition, the spindle can usually move up and down for a third axis. CNC routers are typically work with high speeds and are often used in wood carving.

Router bits can be found at the end of the spindle on a CNC router. The cutting tool in a router can cover a larger area than is possible with a vertical mill. The table, and thus working area, on an industrial CNC router can be 8’ x 4’ or larger, meaning a router will occupy more floor space.

The trade-off for this flexibility is a structure that’s nowhere near as stiff as a mill. This means cutting forces must be kept lower to avoid spindle deflection, which would reduce accuracy. To compensate for shallower depths of cut the spindle turns far faster than that in a mill. Another consequence of lower stiffness is that a router can’t cut steel and tougher materials. However, wood, and soft metal can be cut quickly and accurately.

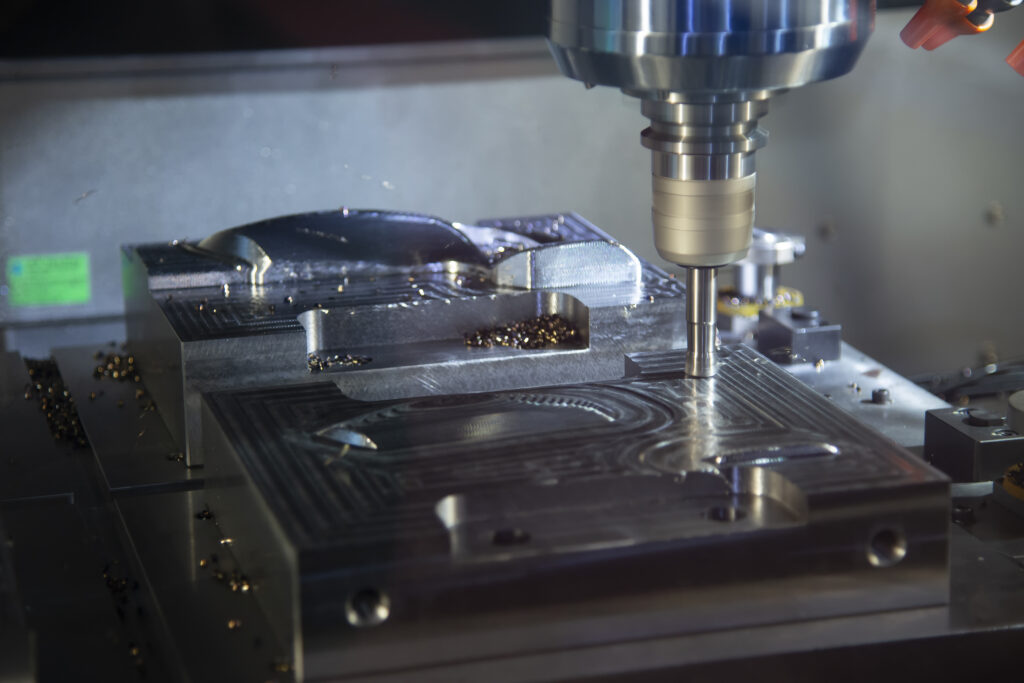

CNC Mills

CNC milling machines or “mills” remove the material with a rotating cutter. This cutter is called an end mill. End millscut laterally into material, creating slots or profiles. Although they seem similar, end mills are more versatile than a drill bit.

CNC mills come in two forms: horizontal or vertical, where this describes the spindle orientation.

Horizontal mills are specialized pieces of machinery often reserved for more complex projects. With horizontally oriented tooling, the rotating cutters can move up to 5-axes to create an end product. These 5-axis machines make complex, high precision cuts and are ideal for large materials, irregular parts, or 3-D tasks.

On the other hand, vertical milling machines are far more common and varied. With a vertically oriented spindle, these milling machines are straightforward for more short-run applications. They range from compact machines for hobbyists to large and powerful models used in industrial machine shops.

CNC Router or Mill?

In summary, the main difference between the two are the type of materials. A router is for machining softer materials. These soft materials are normally woods or plastics. A mill is for machining harder materials and metals. Both can machine aluminum.

Routers can be equipped with a large, stationary table for machining workpieces that come in long sheets. On the other hand, mills are focused more on the thicker and deeper cuts, meaning they tend to take up less floor space than routers. Because CNC mills are for deeper and more complex cuts, they tend to be more expensive than routers.

Make the Right Decision with The Equipment Hub

If you’re trying to choose between a CNC router or mill, speak with someone who knows what you need and what is available. Experts at The Equipment Hub know machine tools and can help you make the right choice. With an inventory including used CNC milling and router machines, you can trust The Equipment Hub to help find the right tool for your industrial needs. Contact us today and explore our inventory of used machines.

Sign Up for Our Newsletter

Sign up for our newsletter using the form below to get company insights and updates directly in your inbox!