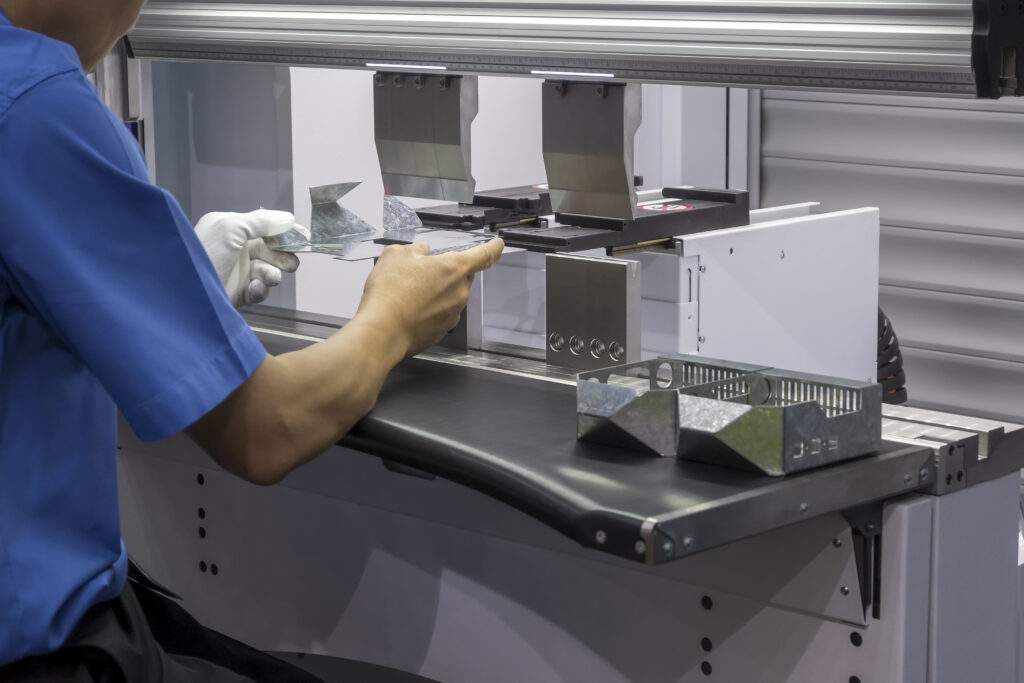

Press brakes are used throughout machine shops, precision machining and other metal fabrication & manufacturing processes. The reliability and repeatability of this machine makes them ideal when needing to bend heavier types of sheet metal due to the amount of force that it expends. You can make small components or large and long parts with the use of this machine.

If you are interested in purchasing a used press brake for your fabrication operations, here are some important considerations to make before accepting a quote.

Which Press Brake Do You Want?

There are several types of press brakes to select from for your operations. Press brakes are categorized by the method in which they exert the force into bending the sheet metal. Types of press brakes available include the following:

- Mechanical Press Brakes: Mechanical press brakes use electric motors to operate the flywheel which pushes the ram down onto the metal sheet.

- Hydraulic Press Brakes: Hydraulic press brakes rely on a pair of hydraulic cylinders that operate on sides of the press.

- Pneumatic Press Brakes: Pneumatic press brakes use air pressure to move the rams much like hydraulic presses.

- Servo-electric Press Brakes: Servo-electric press brakes use two servo motors that are synchronized to move belts and pulleys that transfer power to the ram.

- Hydra Mechanical Press Brakes: Hydra mechanical press brakes are a combination of hydraulic and mechanical systems.

Understanding how you want to power the press break and its functions will allow you to pick out the used machine that can work on your projects.

Technology Available

When looking at used press brakes for sale, many of the newer models have modern CNC control functions so that you can program all the specifications. However, used CNC press brakes may come as older models that contain older technology.

While you could still purchase an old press brake with old CNC control software, keep in mind that the older the technology, the more difficult it will be to service it when there is a problem. OEM CNC software manufacturers may no longer offer the adequate support for older software. If the older CNC console is still serviceable, it could still last for many years. You may also want to see if it is upgradeable in the future.

Tooling

Tooling may be provided with the used press brake for sale. You will want to inspect all tooling for damage, cracks, dents, or excessive wear-and-tear. If you already have tooling in your shop, you want to check to see if the used press brake will use those same tools, whether they are American style, European style or used with a Trumpf Trumabend machine.

Yet keep in mind that if your tools are old, purchasing a used press brake with somewhat newer tools than what you own can give you a host of benefits.

Condition and Age

Since the market for used press brakes is enormous, you will come across press machines in various ages and conditions. You will want to thoroughly inspect the press brake machine and all moving parts for any damage or defects that could require some repairs.

Parts of the press brake that you want to inspect include the ram and the bed. You want to make sure there is no deformation. Also inspect the tool holders that are removable on the arm for any damage or deformation. The backgauge should also be in working order.

Lastly, check out the hydraulic and cylinder systems for any excessive leaking. It’s also important to review maintenance logs to have a better understanding of the history of use.

Your Specific Needs

You may have a specific reason for wanting to get a used press brake. You may be looking for a high quality machine that offers more capacity in tonnage or a longer bed. Other considerations may involve wanting to lower your setup times to perform metalworking projects by having a machine that is easier to use and maintain. The press brake machine may also need to offer improved part accuracy so you can reduce the amount of scrap that is created due to inaccurate bends.

Always seek out a machine that can hit most of these points. Sometimes you may have to trade off one aspect for another, such as obtaining higher accuracy, but the bed is shorter than desired. Yet strive to find a used press machine that meets most of your desired needs.

Operator Skill Level

Always keep the skill level of the operator in mind when obtaining a used press brake if you plan to put it into use immediately. If you have an operator that is not highly skilled, consider purchasing a used CNC press brake with somewhat newer controls and functions. With this added automation and controls, the machine will do most of the calculations, gage points, and bend sequences automatically. Also, with more controls to the machine, the easier it will be to set up in operations.

Used Press Brakes & Other Equipment

Take your time and evaluate your current shop setup to decide on the size of the press brake you need, such as 60 ton, and the features that are desired for your operations. Then turn to Equipment Hub. We offer a vast selection of press brakes and other used equipment for manufacturing and fabrication shops. Contact us today to learn more.

Sign Up for Our Newsletter

Sign up for our newsletter using the form below to get company insights and updates directly in your inbox!